We can upgrade your existing UTM (also from other manufacturers)

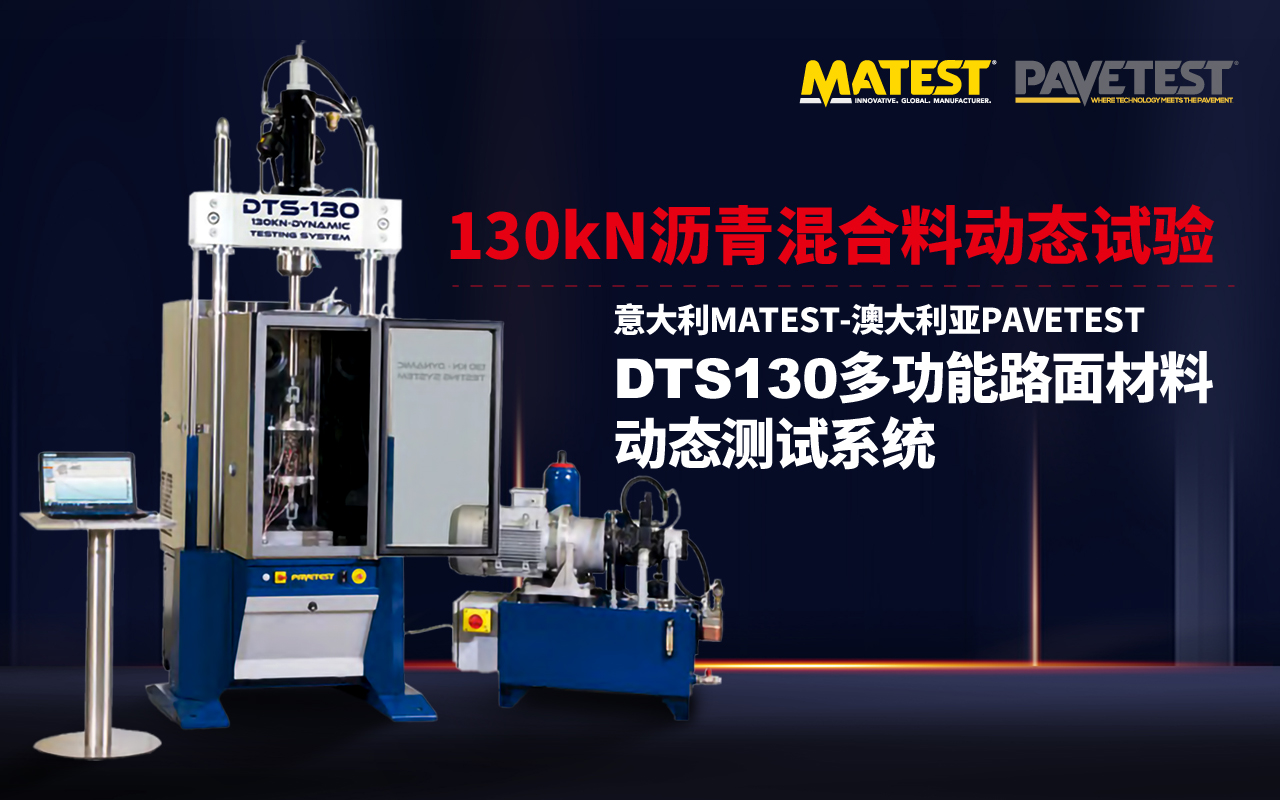

The DTS-130 Dynamic Testing System is a servo-hydraulic testing machine utilizing digital control of a high performance servo valve to provideaccurate loading wave shapes up to 100 Hz. The DTS-130 is Pavetest’s capacity Dynamic Testing System and completes the range ofstandard universal testing machines. The system can be operated in tension, compression dynamic loading and is suited to testing a diverserange of engineering materials and/or large asphalt specimens at cold temperatures.

The DTS-130 is underpinned by Pavetest's CDAS digital controller, TestLab software and a full complement of accessories, hardware and software in unison.

The Hydraulic Power Supply (HPS) utilizes a variable flow pump with a working pressure up to 210 Bar. The customer can choose either water(heat exchanger) or air (Electric fan) oil cooling. Features include; low oil, over temperature and dirty filter indication, remote starting and userselectable working pressure (via TestLab).