APS (Wille Geotechnik®) has been successfully manufacturing and providing variety range of Shear testing devices for geotechnical applications for many years in different ranges. These products give a lot of flexibilities to the users to run tests with high accuracy and add different upgrading module to system to reach the required testing applications. The temperature control package with the high accuracy and performance makes the possibility to run the tests under different temperature conditions from frozen tests up to high temperature ones. A unique and flexible software along with components bring you different possibilities to use the device and run your test in a better way.

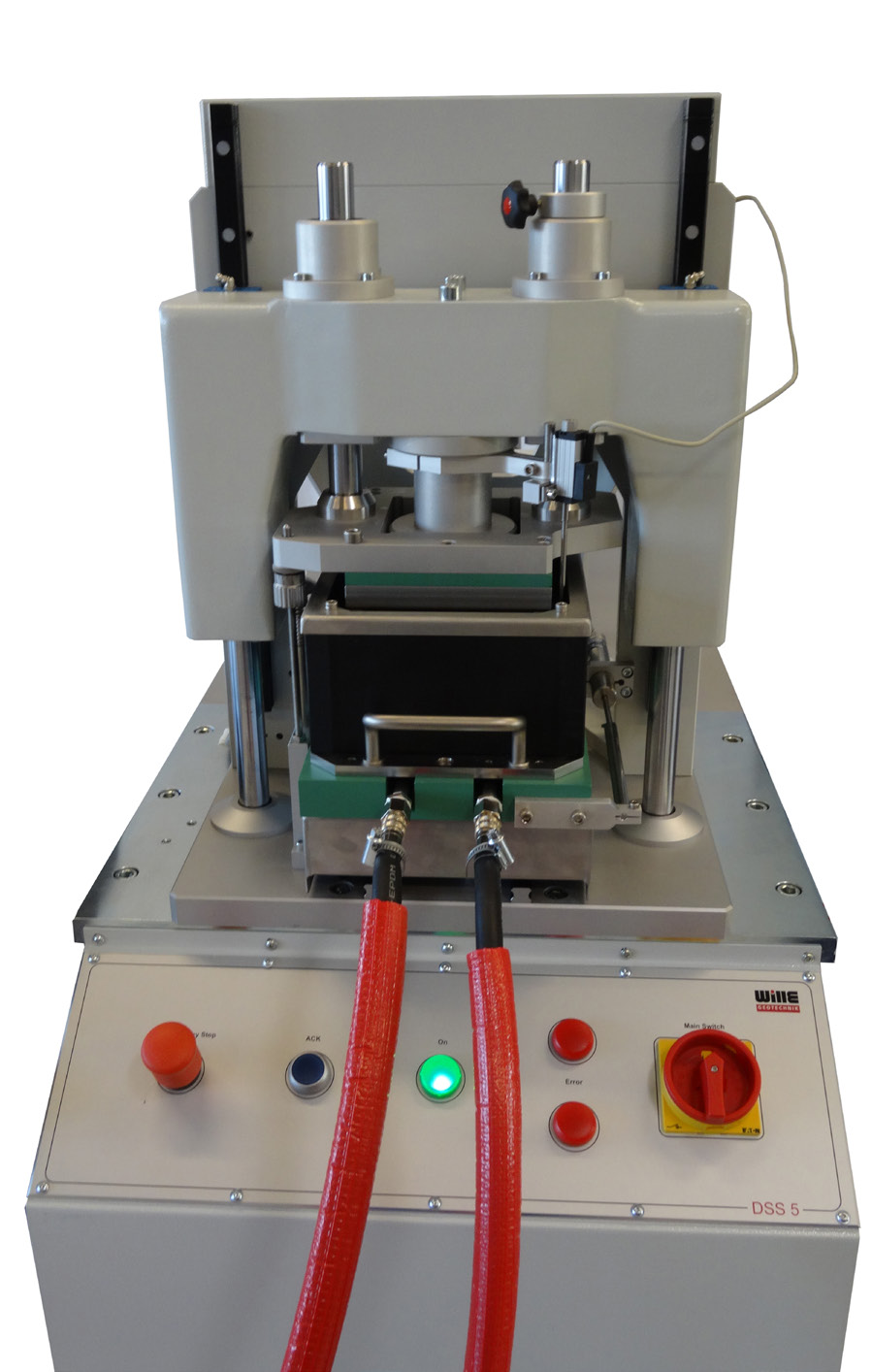

This series of stand-alone electromechanical shear testing devices are designed and manufactured to perform shear tests on soil under different temperature conditions. Many tests require temperature controlling of specimen either for high temperature or for low temperatures and this requires new designed system which would be able to avoid any temperature gradient in sample during tests and make a unique constant temperature condition for the period of testing. The system can be customised in variety test conditions e.g. Static loads with electromechanical motor, different sample sizes either in simple shear or direct shear test format, Low temperature tests or/and high temperature tests which all can be configured together to meet the test requirements.

The temperature controlling system can control the temperature of sample in range of -30°C up to +200°C. The main advantage of device is an accurate testing of soil parameters without tilting and friction between shear box components (e. g. load piston, upper shear box, lower shear box).The normal stress and the shear stress are closed loop controlled by an electromechanical drive system.

The powerful GEOsys software supports all the test procedures with well access to all testing sessions and also gives this feature to manage and run customized test procedures per as any testing needs.

System Geography

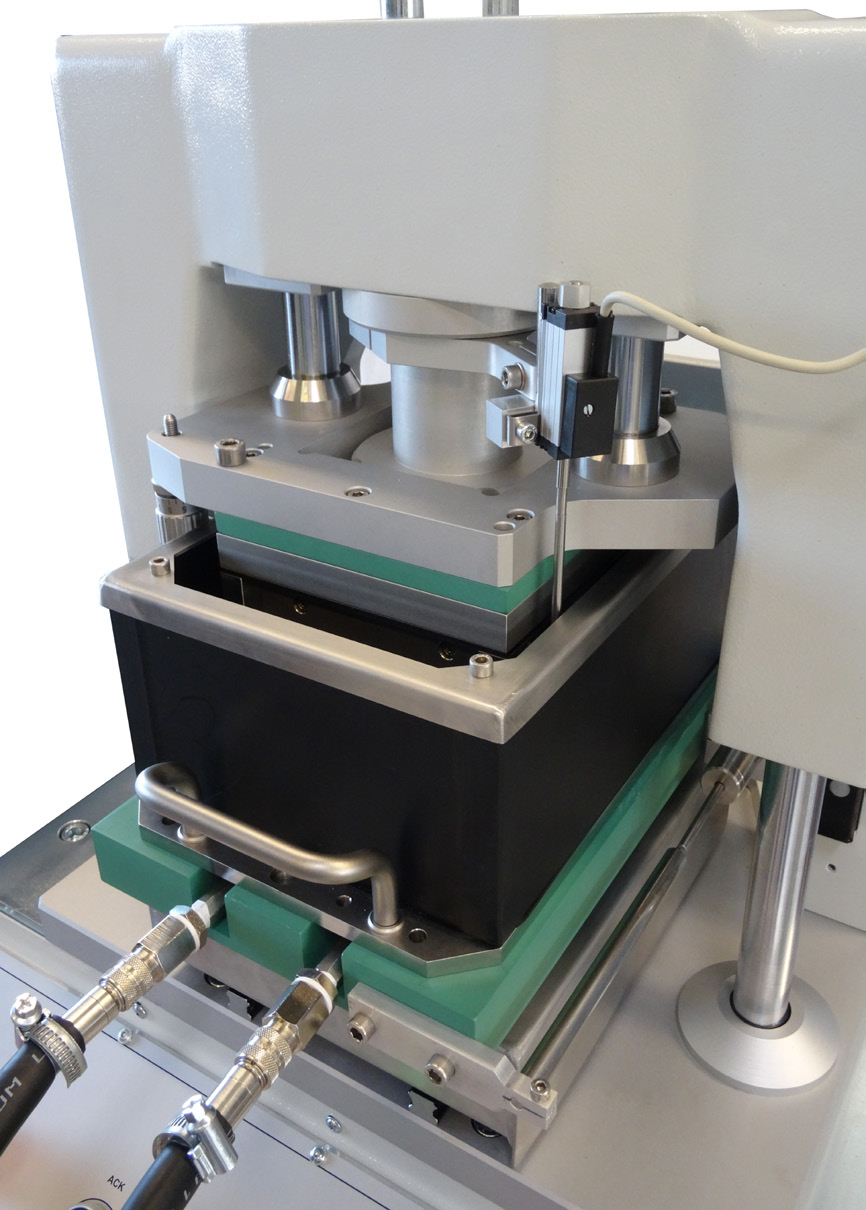

① Electromechanical Stiff stand-alone Load frame

② Two columns beam to mount the linear guides

③ Two stainless steel pillars to further brace the system

④ Upper traverse

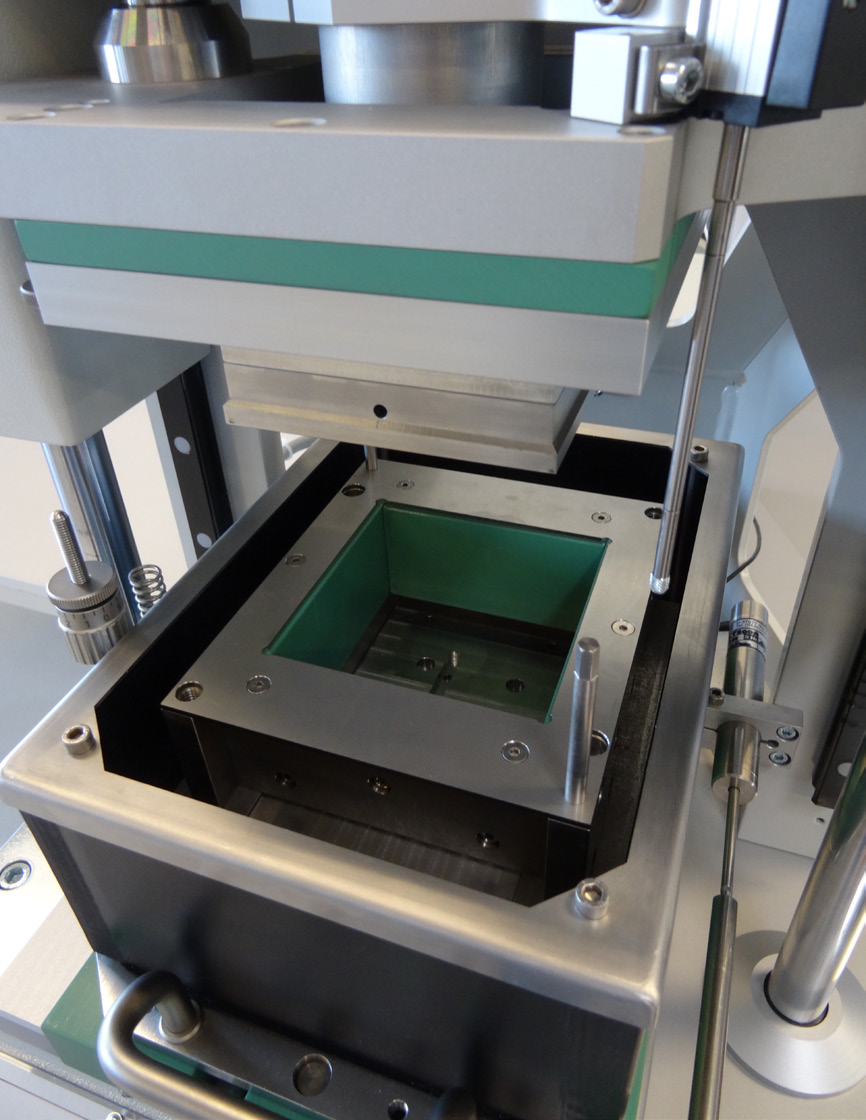

⑤ Thermal Direct Shear Test Jig

⑥ Front operational panel (On-0ff switch button, Stop button)

⑦ High quality and low friction double linear guides

⑧ Heating and cooling system controlled by GEOsys software

⑨ Unique 2-dimensional double Shear force load cell (Invisible)

⑩ High Speed dynamic Controller

Cyclic Direct-Residual Shear Apparatus

The Cyclic Direct shear apparatus is an automated apparatus with a very high stiffness and includes of two high quality servomotor drives for performing vertical and horizontal shear load (static and dynamic). The electromechanical drive with high resolution and closed loop control rate generates closed-loop strain and stress controlled static axial load and strain and in addition stress-controlled shear forces.

The Vertical load is performed by an actuator connected to the top of the specimen, which is rigidly fixed against horizontal movement and just perform vertical load with high accuracy. It is included of a high-resolution internal displacement transducer to measure the movement of the piston with high accuracy along the height of specimen.The other actuator performs horizontal load to the bottom of the specimen and causes shear strain.

The main advantage of device is an accurate testing of soil parameters without tilting and friction between shear test components. The high quality and low friction double linear guides used to ensure strength and alignment without tilting in normal and shear directions.

Shear Box

The complete shear box system is made of stainless steel and is designed to contain water that surrounds the specimen and allows the specimen to be submerged for saturate conditions. The shear box consists of lower and upper shear boxes with rigid wall either in round or square shape, adaptor loading pad, two porous plates, load piston, sample cutter, dolly and water container for saturated conditions. The Lower part of shear box is locating on a low friction bearing and moves with the small friction just in horizontal direction while the upper shear box is fixed.

The Shear box comes in different sizes e.g. :

• Square:60 x 60 mm ( 36c㎡)

• Square:100 x 100 mm (100c㎡)

• Circular:Ø 60 mm (28.27c㎡)

• Circular:Ø 71.4 mm (40c㎡)

• Circular:Ø 80 mm (50c㎡)

• Circular:Ø 94.4 mm (70c㎡)

Temperature Control Package

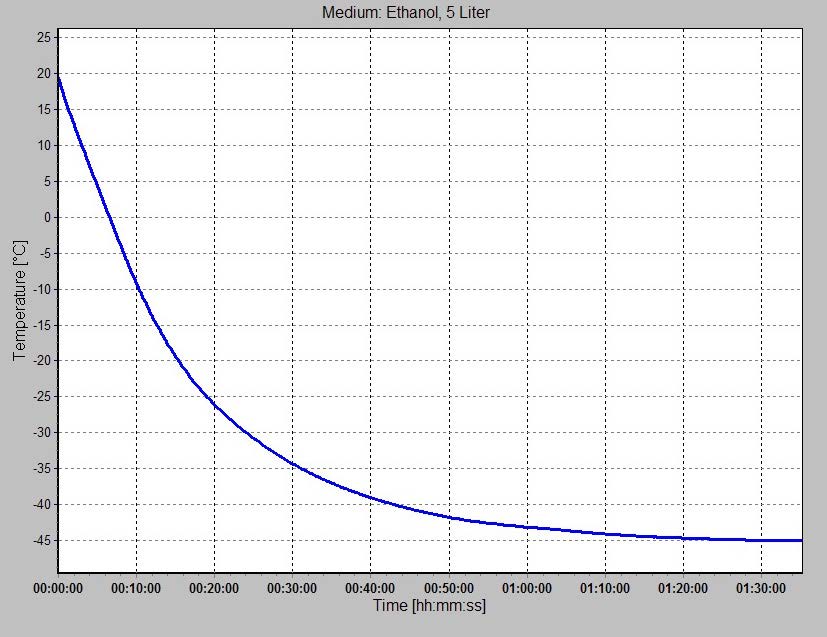

The shear box with relevant accessories allows the user to control and monitor the temperature of the sample in different ranges e.g:

• -30 °C to Ambient temperature

• From ambient temperatures to +200°C

• From -30°C to 200°C

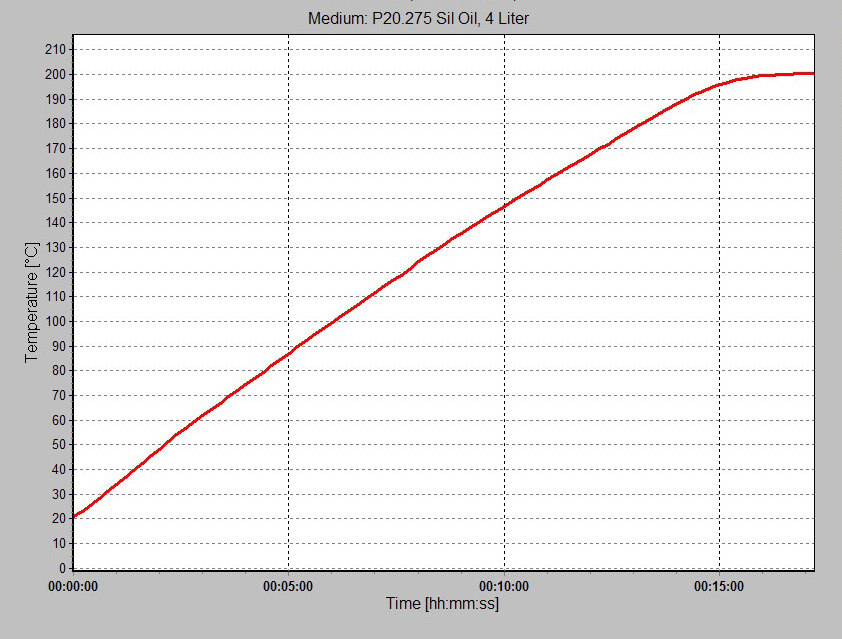

Thermal Loading

The Soil – Structure or Soil/Soil direct shear test machine provides a thermal module to apply thermal loadings in the range of required temperature. Three types of thermal loadings are available: constant, ramp and sine.

The temperature control package includes of different item which are listed shortly as below

• Temperature control cryostat (heating/cooling)

• Thermal insulation package for shear box to temperature loss

• Thermal insulation package for all pipes between shear box and temperature control device

• Two temperature sensors to measure temperature of sample and provide a closed loop control for performance of thermal loading (one sensor is located inside the lower box and the other one is located on top plate)

• Ceramic isolation plate between load piston and sample

• Control and data acquisition Software-Module for PC control of all functions of the heating system (including cable connector and protocol)

Temperature Control Device(Heating-Cooling)

The refrigerated Heating Circulator Bath with air-cooled cooling machine is suitable for controlling the temperature of externally connected objects/applications and thermoregulation of objects directly in the thermostat bath.

• temperature control

• Insulated baths made of stainless steel

• Large display 5.7” touchscreen with graphic functions and a comfortable navigation menu

• Multi-touch controller with Plug & Play technology

• Powerful pressure/suction pump

• All-important operating parameters and temperature values are neatly displayed on the touchscreen

• Integrated USB and Ethernet ports allows connection to a PC or network, e.g. for remote control or data transmission

• 5-point calibration

• Pt100 sensor connection

• The circulator is fitted with a temperature-controlled cover plate to avoid the formation of condensation and ice

Digital Controller

Digital High-Speed High Resolution Expandable Real Time Control and data acquisition System 10KHz control and data acquisition and 24 bit resolution. The Dynamic controller is suitable for screw driven instruments(electromechanical) , hydraulic instruments with a valve driven with ±10 Volt and variety of sensors e.g. load cells, LVDTs, strain gauges, extensometers, thermocouples and etc.

The multi-functionality of the controller allows a modular design of the measurement and control parameters (sensors) via intelligent sensor plug, which store the calibration parameters, thus depending on the application can be used flexibly.

Main Features

• Up to 32 low-noise closed-loop control channels for static and dynamic tests

• up to 24-bit resolution channels for each test axis (e.g. force, displacement, pressure, strain)

• With digital controller parameterization and bumpless switching between all control functions

• Smooth changeover between all control functions

• Complete, simultaneous data transmission to avoid any data loss

• Digital adjustable controller parameters (P-I-D parameter)

• Simple and flexible test or setpoint parameter adjustment

• I/0 processing of externally connected

• Configuration and setup with PC software