GEOSYS Software

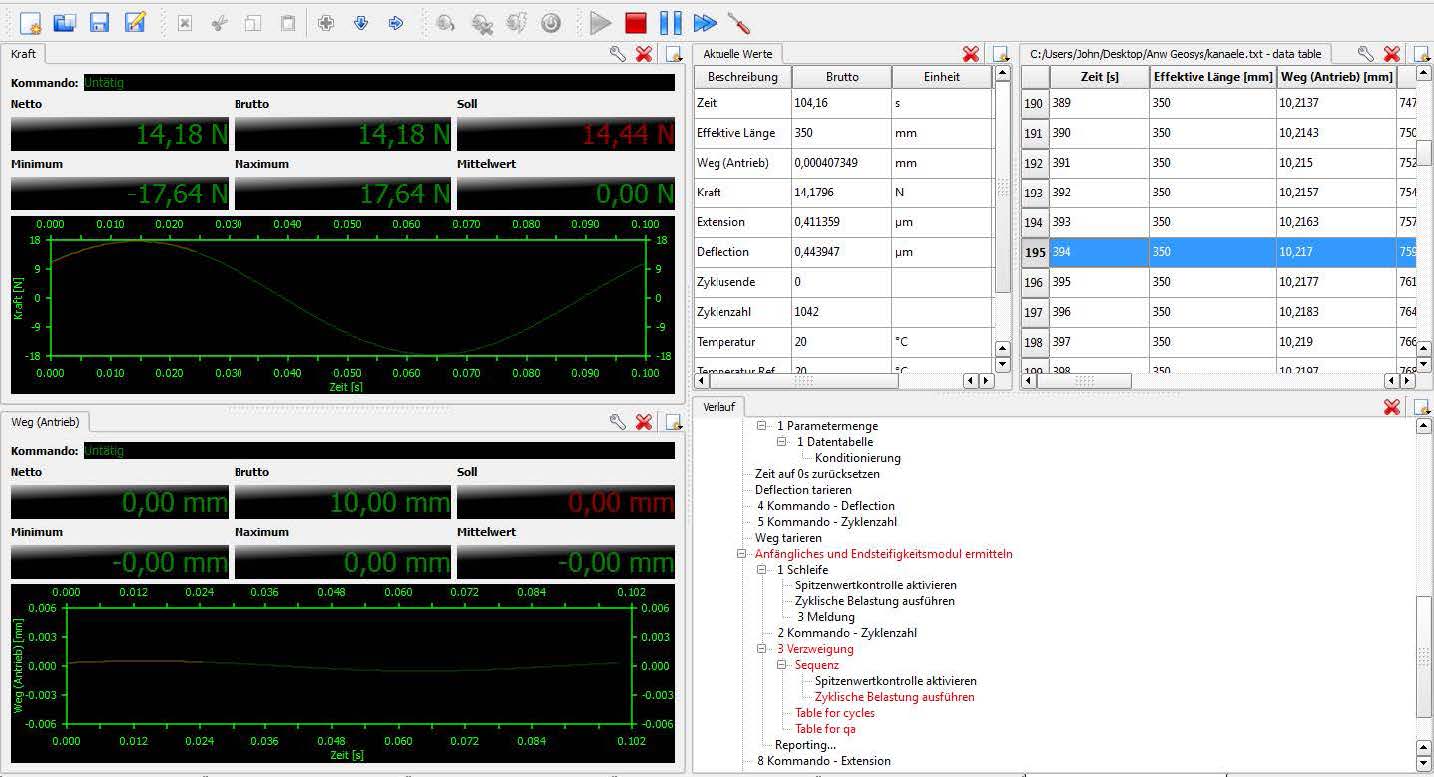

GEOsys is a multi-functional and modular controlling and data acquisition software in Windows. It allows for the simple programming of complex user defined test sequences via structured Windows instructions on a graphi cuser interface.

GEOsys utilizes a flexible, programmable system that controls test appliances that coordinate various test operations. The flexible operating panel provides tools to configure the appliance, editors to carry out load procedures, and functions for analysis, presentations and logs. The software is designed to support a modul arstructure for the test environment so as to enable a flexible configuration and thus fulfil the specific requirements of the company.

The important key feature of this software is the ability to allow users to simply and freely program standard or complex test sequences with structured Windows operations via a graphic user interface.

Thanks to the wide range of abilities Geosy soffers, it is not only compatible with our products, but it can also be used with hardware from other manufacturers, providing data acquisition and test controlling for hard- ware of a similar or more advanced standard.

Main Features

• Unique platform to address all testing needs, be it soil, asphalt, rock or construction related, both dynamically and statically

• Controlling and data acquisition software

• Simultaneous loops for all connected actuators

• Free programmable Test Sequence Control and Formula Editor (upgrade version)

• Complete real-time data-acquisition and closed- loop control for each channel using real parallel configured channels

• Flexible and user-friendly

• Supporting functions of similar manufacturer Options concerning data conversion in ASCII

• Digital setting of PID Parameters (parameter optimizing or tuning depending on the material) even during operation

• User roles (administrator, service, developer, lab assistant) for easy handling – decreasing the likelihood of errors

• OS platform independent software (e.g.available for WINDOWS, LINUX or MAC OSX)

• Ability to allow users to simply and freely program standard or complex test sequences with structured Windows operations via a graphic user interface

• Suitable for up to any number of simultaneous and independent real-time, closed-loop controlled channels, machines, or test devices, such as axial load, confining pressure, pore water pressure, as pore air-pressure

• Management of hardware components User supplied, calculated measurements

• Languages: English, German, Russian, Chinese, Polish and etc

Soil Triaxial Test Modules (Static & Cyclic)

GEOsys is designed for closed-loop controlled static & Dynamic tests for all test applications in material testing, such as stress-controlled, strain-controlled, all stress paths, loops, any kind of waveforms like sine, rectangle, triangle, and predefined waves.

It is controlling and data acquisition software and also has different modules to run tests according to ASTM or BS or other standards. Please note that some tests listed below will require optional hardware. Depends on the requirement of the customer one or several modules would be delivered with main software, such as:

• Data Acquisition, processing and device management (DPD) Module

• Saturation Module

• B-value -Test Module

• Consolidation Module (Isotropic or anisotropic)

• Permeability Test Module

• Stress path module: Linear stress paths- p, qor s, t

• Static Shear Stage Module:

UU: Unconsolidated Undrained Triaxial Test (Total Stress test)

CU: Consolidated Undrained Triaxial Test with pore pressure measurement (Effective Stress test)

CD: Consolidated Drained Triaxial Test with pore pressure measurement (Effective Stress test)

• Unsaturated Test Module

• K0 Test Module

• Tension (Extension) Test Module