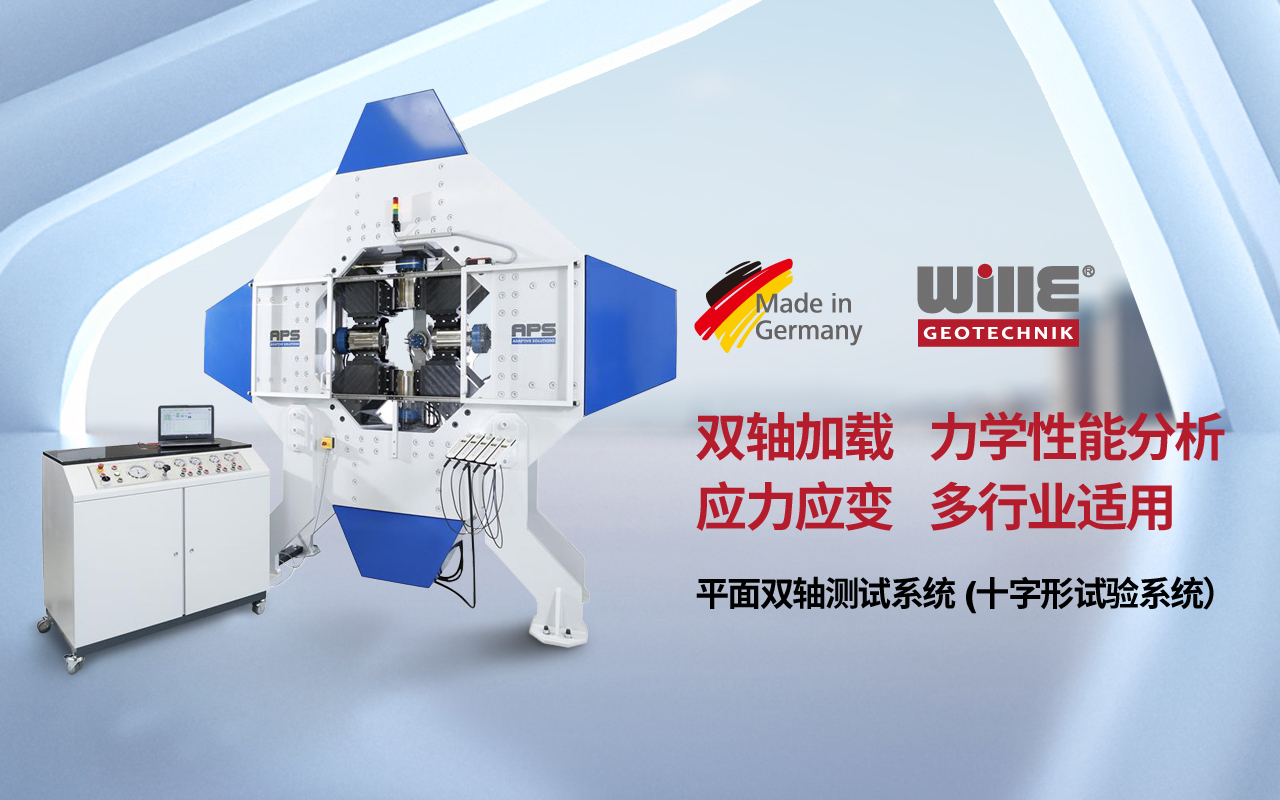

Wille Geotechnik® Multiaxial loading technology of the brand markWille Geotechnik® incorporate an extensiverange of features making them ideal for applyor measure in- plane stresses in both X and Ydirections on a cross- shaped specimen with useof 4 different dynamic actuators. It helps to Itdetermines a specimen’s mechanical propertiesin its different points and analyze the stress andstrain distribution.

The main reason to use planar biaxial test deviceis for specimens which are anisotropic e.g. metalsheets fiber-reinforced composites and etc. Theyhave different mechanical properties in different directions due to manufacturing process of themtherefor needs to be tested in multiple directions.The testing device allows to simulate a real-worldcondition.

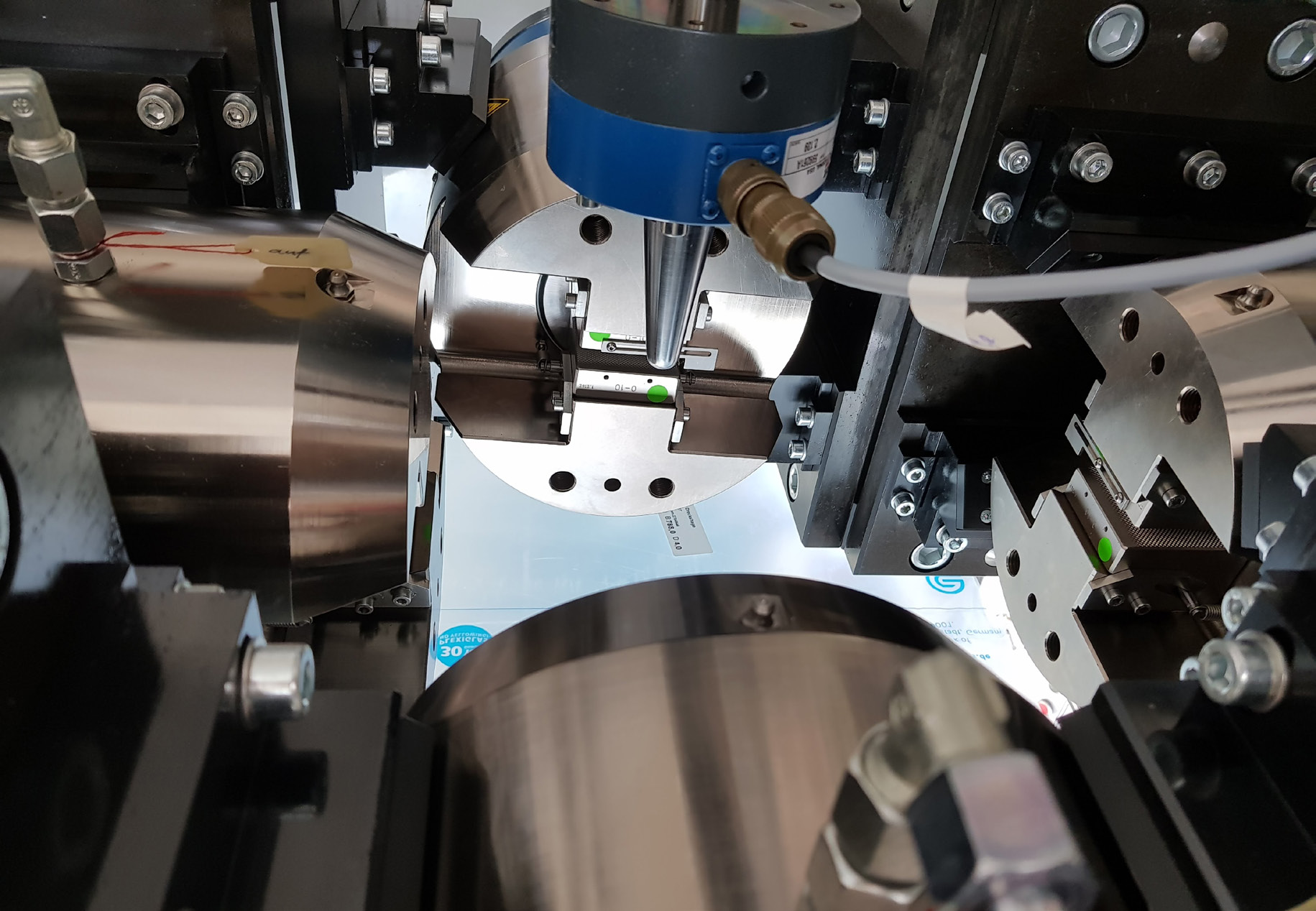

Each actuator is controlled separately and canmoves in equal or opposite directions in eachaxis so that the center point of sample remainsstationary.

The system can accept different shaped cruciformspecimen e.g. straight arms, curved arms or etc. All the package is designed and manufactured tocharacterize the mechanical properties and thestress-strain behavior of the material adequately.

Genral Description

The system includes of a high stiffness load frame combined with 4 dynamic actuators mounted perpendicular toeach other and in-plane to apply compression or tension loads in X and Y directions, load cells, hydraulic powerpack to provide the required oil flow for actuators, controlling cabinet which includes of data acquisition system,Hydraulic or mechanical grips , strain measuring device and dedicated software to run the tests.

This series of machines comes with different load range which would be from 25kN for each actuator to 500kN.We offer different frame sizes for different load capacities. The size of load frame for temperaturecontrolled testsis different from the ones which is suitable fo r ambient test condition.

Users

There are variety industries which could take advantages of testing results with multi-loading systemfor the study of materials e.g.:

• Heavy industries

• Aerospace industries

• Power generation industries

• Vehicle industries

• Engine turbine industries

• Large scale wind turbine structures

• Construction industries

• Oil and gas upstream industries (exploration)

• Oil and Gas Downstream Industries

Testing Specimen/Materials

Metal Alloys、Steels、Aluminum Alloys、Polymer reinforced composites、Magnesium Alloys、Titanium alloys、Composites、Ceramics、Composites、Textiles、Concrete

Control Panel

The control panel of the system includes ofdifferent buttons, indicator lights, manometersand main duty of it is controlling and dataacquisitioning of the system.

The buttons are for Emergency stop button, fullpressure, pilot pressure and manometers are forGrips pressure and system hydraulic pressure.There are a manometer and 3 buttons peractuator as well to make it easier to use each ofthem individually.

Including high resolution data acquisition systemup to 21 bit resolution with expandable up to 32(or more) high speed, low noise channels for dataacquisition or closed-loop control (feedback) foreach actuator (load, displacement, pressure, etc.)

High performance technology permits theexecution of static and dynamic asphalt ormaterial tests as uniaxial or multi-axial tests(stress-path triaxial tests) in real time modes.

The multi-functionality of the controller allows amodular design of the measurement and controlparameters (sensors) via intelligent sensor plug,which store the calibration parameters, thusdepending on the application can be used flexibly.

High performance technology permits theexecution of closed-loop controlled load (stress),displacement (strain) or position controlled testsin real time modus.

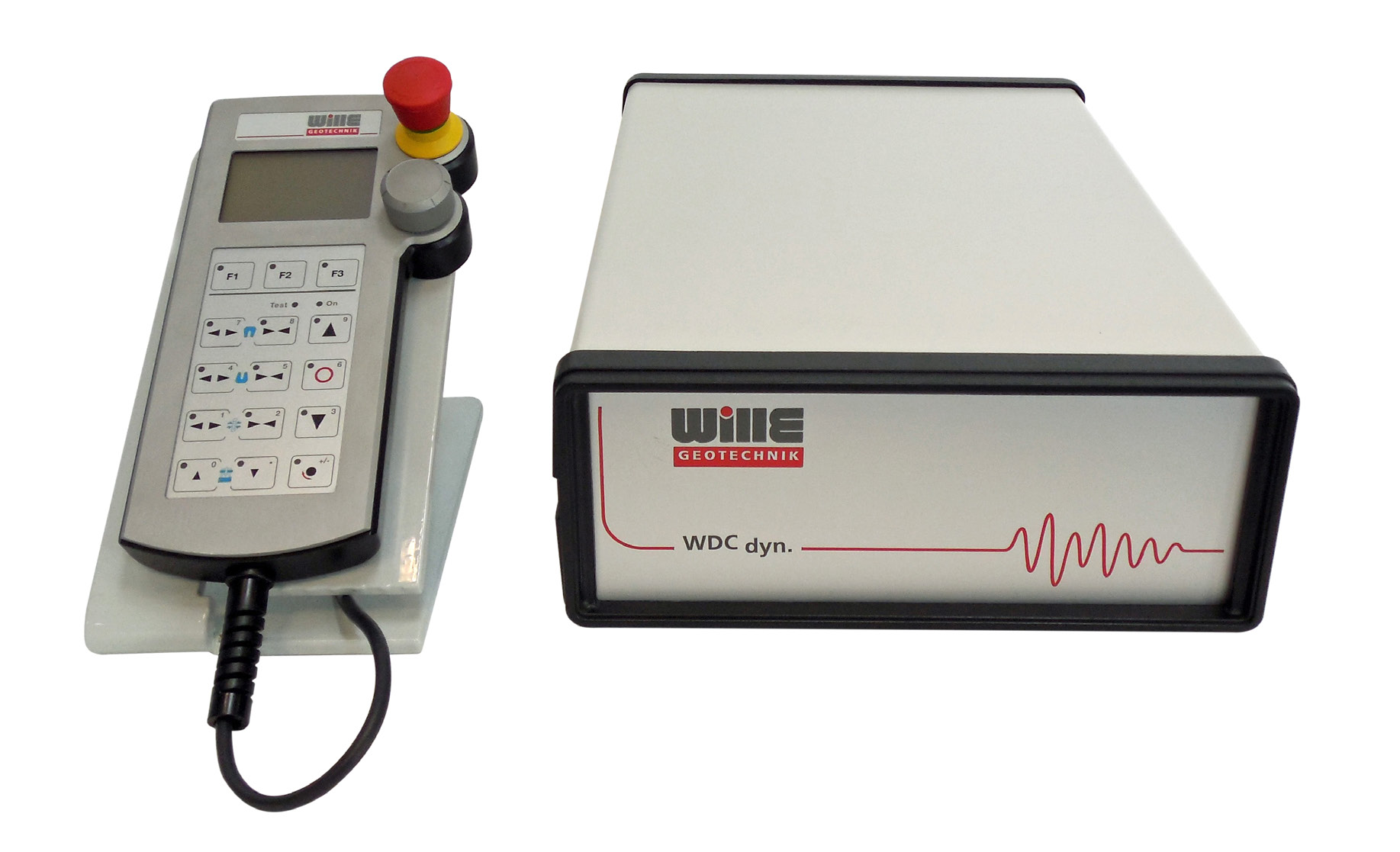

High Speed Dynamic Controller

Digital High-Speed High Resolution ExpandableReal Time Control System including 24 bit highresolution data acquisition system, expandableup to 8 or 32 high speed low noise channels fordata acquisition or closed-loop control (feedback)for each actuator.

The multi-functionality of the controller allowsa modular design of the measurement andcontrol parameters (sensors) via intelligentsensor plug, which store the calibrationparameters, thus depending on the applicationcan be used flexibly.

Synchronisation Of Several Wdcdyn

This option is needed for synchronization of data acquisition and motion control amongst several WDCsystems. All necessary signals are transmitted via a serial RS485-bus and up to 32 WDC-Units may beconnected to this bus. This gives the highest possibility to have enough channels for different testingpurposes.

Remote Control

This remote control is a handheld unit (cable 3m) which directly connects to the maincontroller. The control keys and a small display and control LEDs for the TEST- and thePOWER-function is available on front of the unit. It has a magnetic foil on its back andtherefore can be placed at an ergonomic position.

The hydraulic cylinders can be controlledand operated individually by meansof the remote controls in order to setup the machine for operations thatmeans tehre are 5 Remote controllerswhich four of them are for 4 differentdynamic actuators and one for Impacttest actuator. The dimension of eachremote controller is: L 25 x W 65 x H202 mm.

Rear View Of The System

The hydraulic components of the machine are located behind the maintenance door of the hydraulicsystem. A drip tray to catch any leaking hydraulic fluid is located beneath the hydraulic components.Hydraulic distributor Pressure is distributed by means of the hydraulic distributor via the individualhydraulic hoses.