Differential Scanning Calorimetry (DSC) is one of the frequentlyemployed thermal analysis methods. It can be used to analyze nearlyany energetic effect occurring in a solid or liquid during thermaltreatment.

Easy handling and rapid analysis are among the hallmarks of this analyticaltechnique, which has proven to be highly significant in the areas of research,development, and quality control. There are a variety of standards (ASTM, DIN,ISO, etc.) for the application, evaluation and interpretation of specific materials,products and properties.

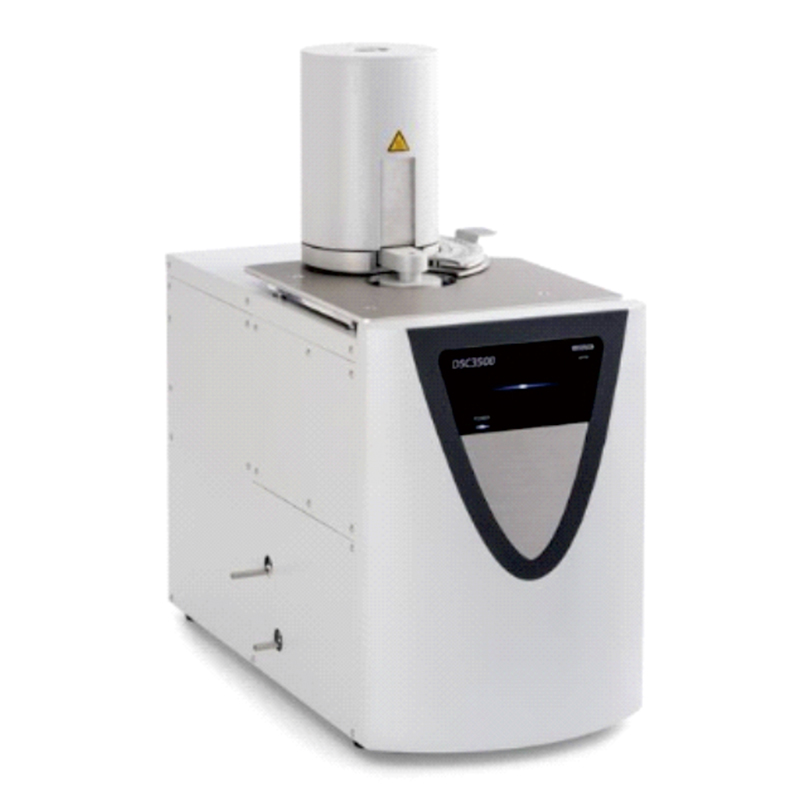

The DSC 3500 Sirius operatesaccording to the heat-flux principle.With this method, a sample and areference are subjected to acontrolled temperature program(heating, cooling or isothermal).The actual measured properties arethe temperature of the sample andthe temperature differencebetween sample and reference.From the raw data signals, the heatflow difference between sampleand reference can be determinedwhich represents the caloricchanges of the sample.

The gas-tight DSC 3500 Sirius combinesthe advantages of modern technology,high sensitivity and a robust, easy-tooperate workhorse. Tests can be carriedout in the temperature range between-170°C and 600°C.

Key components of the DSC 3500 Siriusare the DSC heat-flux sensor, the furnaceand clever connection fittings which aredesigned for the quick and easyattachment of various cooling systems.

The sensor of the DSC 3500 Siriuscombines high stability and optimizedresolution of thermal effects. Laserguided welding processes for the sensordisks and thermocouple wires yield truesensitivity and robustness.

DSC features:

• Determination of onset, peak, inflection and end temperatures

• Automatic peak search

• Transformation enthalpies: analysis of peak areas (enthalpies) with selectable baseline and partial peak area analysis

• Evaluation of Crystallization

• Comprehensive Glass Transition analysis

• Automatic baseline correction

• Specific heat determination

• Tau-R® Mode: takes into account the time constant and thermal resistance of the instrument and reveals thus sharper DSC effects from the sample (optional)

• Optional TM-DSC (temperature modulation) for separation of reversing (thermodynamic) and non-reversing (kinetic) effects